Condenser and Heat Exchanger Tube leakage can cause many operating system issues. A tube leak can be as simple as leading to poor operating performance or can be as significant as introducing contamination into plant systems.

Hennigan Engineering utilizes a wide variety of methods and equipment to identify leaking tubes. These tube leak detection methods include, but are not limited to, Helium Leak Detection, Hydostatic Testing, Dimple Testing and Ultra Sound Methods.

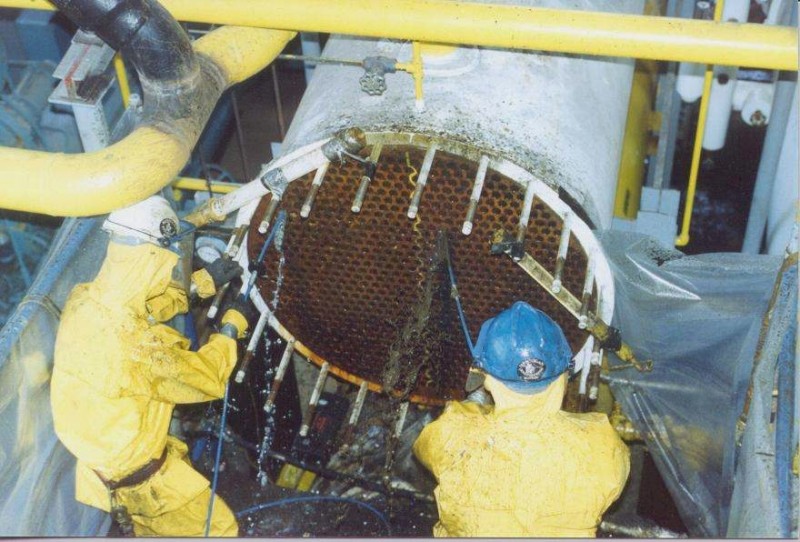

Upon identification of the defective tube Hennigan Engineering has qualified tube plugging technicians that can perform effective tube plugging.

Looking over a long history of Hennigan’s service to Canal Electric Company, I wanted to take the opportunity to commend you for many jobs well done! In an era of uncertainty, it is reassuring to have the certainty of reliability, professionalism, and the commitment of excellence in service.Canal Electric

In conclusion, it is Design Engineering’s recommendation to use Hennigan Engineering to clean any of the-RBS heat exchangers during RF-3 that need cleaning. Hennigan’s past performance plus their patented hydrolasing tip make them the logical choice to use here at RBSRiverbend Nuclear Group

I would like to take this time to express the quality of work that Hennigan Engineering performed during the repair of the USNS Gordon for Boston Ship Repair, Inc. Hennigan Engineering showed professionalism in all aspects of the work that was performed in the shipyard. Work was done in a timely and efficient manner.Boston Ship Repair, Inc.

Or give us a call directly to discuss your condenser leakage testing needs:

800-472-8484