Service and Circulating Water Piping condition has become a significant problem in our aging infrastructure, often referred to as Buried Piping. Many plants are now required to have a Buried Piping program. Hennigan Engineering offers many services for assisting with your Buried Pipe Program. These services include, but are not limited to, video inspection of as-found conditions, Hydrolase Cleaning of piping to determine condition of coating or underlying base metals, removal and disposal of debris, treatment of contaminated or non-contaminated water, spot repair of coatings or complete pipe relining.

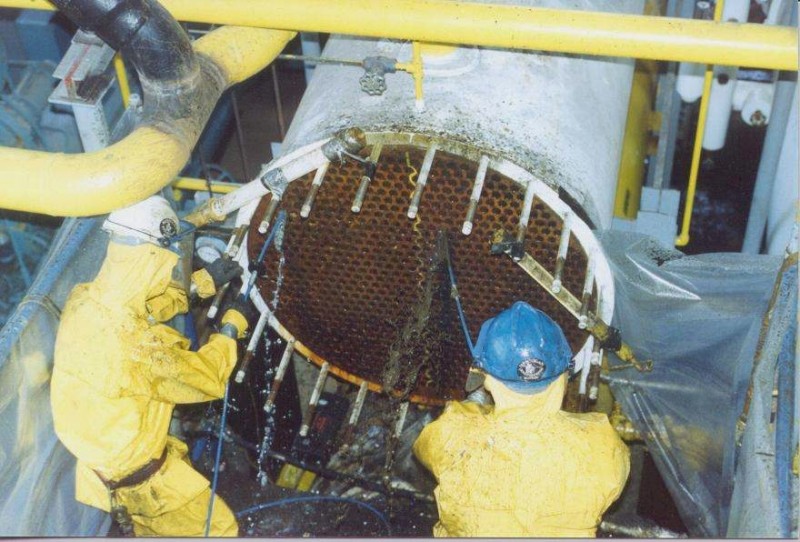

One of Hennigan Engineering’s core service offerings is the restoration and maintenance of condenser tubes to design specifications or to the maximum available operating efficiency utilizing various cleaning techniques. These include condenser tube cleaning techniques such as chemical cleaning, hydrolase cleaning and projectile cleaning. Proper assessment of the conditions affecting each unit is crucial in choosing the correct course of action. We work closely with our clients to offer a comprehensive cleaning solution, taking into account tube base metal compositions, base metal conditions, corrosion control, fouling agent, scale composition, cleaning window, safety and environmental concerns. Based on application, tube condition and overall plant objectives, we implement cleaning operations that best meet the tube condition, fouling substance removal plan and the customer’s budget.

We rely heavily on the use of specialized high pressure water jetting equipment to satisfy the majority of our project requirements. We have custom designed our high pressure water jetting systems to perform far beyond the capability of off-the-shelf equipment. The net result is a package designed to provide complete 360 I.D. tube cleaning without harming tube base metal. With operating pressures ranging from 10,000 – 20,000 psi, we can effectively remove all foreign debris, from biological films to calcium/silica scales.

Looking over a long history of Hennigan’s service to Canal Electric Company, I wanted to take the opportunity to commend you for many jobs well done! In an era of uncertainty, it is reassuring to have the certainty of reliability, professionalism, and the commitment of excellence in service.Canal Electric

In conclusion, it is Design Engineering’s recommendation to use Hennigan Engineering to clean any of the-RBS heat exchangers during RF-3 that need cleaning. Hennigan’s past performance plus their patented hydrolasing tip make them the logical choice to use here at RBSRiverbend Nuclear Group

I would like to take this time to express the quality of work that Hennigan Engineering performed during the repair of the USNS Gordon for Boston Ship Repair, Inc. Hennigan Engineering showed professionalism in all aspects of the work that was performed in the shipyard. Work was done in a timely and efficient manner.Boston Ship Repair, Inc.

Or give us a call directly to discuss your hydrolase cleaning needs:

800-472-8484