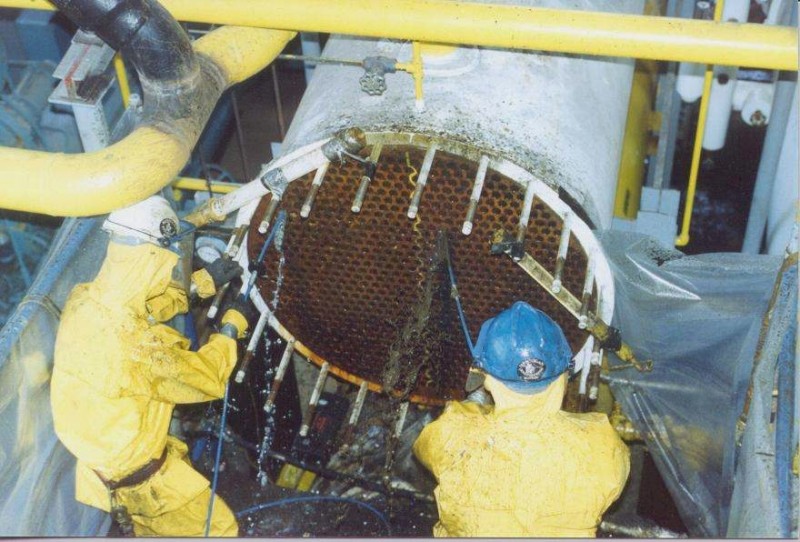

“Hydrostatic Pressure Testing” is a diagnostic technique to check pressure vessels, pipes, and boilers for leaks or defects. The device to be tested is filled with an incompressible liquid, usually water or oil. With the assistance of a positive displacement pump incorporating appropriate safety reliefs and controls, the pressure of the test component is slowly increased to a predetermined set point and held for a predetermined time. Visual inspection is subsequently performed to determine if any leakage exists and if the pressure set point reduces.

Hennigan Engineering deploys the appropriate electric, air or diesel-driven positive displacement pump system as well as experienced personnel to perform our testing. Normal testing utilizes a low volume, medium-pressure (20 psi to 2,000 psi), hydrostatic test pump designed to test low-pressure systems. Larger capacity diesel driven pumps are also available to test large systems or vessels to pressures up to 60,000 psi. The test pump assemblies are complete with an unloader valve or pressure regulator to regulate pressure, a high-pressure discharge valve to isolate the device being tested and a pressure gauge or transducer with a digital recorder that is traceable to the National Institute of Standards and Technology (N.I.S.T.) for certification of the test.

Please feel free to contact us directly regarding case studies on hydrostatic pressure testing.

Looking over a long history of Hennigan’s service to Canal Electric Company, I wanted to take the opportunity to commend you for many jobs well done! In an era of uncertainty, it is reassuring to have the certainty of reliability, professionalism, and the commitment of excellence in service.Canal Electric

In conclusion, it is Design Engineering’s recommendation to use Hennigan Engineering to clean any of the-RBS heat exchangers during RF-3 that need cleaning. Hennigan’s past performance plus their patented hydrolasing tip make them the logical choice to use here at RBSRiverbend Nuclear Group

I would like to take this time to express the quality of work that Hennigan Engineering performed during the repair of the USNS Gordon for Boston Ship Repair, Inc. Hennigan Engineering showed professionalism in all aspects of the work that was performed in the shipyard. Work was done in a timely and efficient manner.Boston Ship Repair, Inc.

Or give us a call directly to discuss your hydrostatic pressure testing needs:

800-472-8484