Traditional abrasive blast preparation is becoming a thing of the past. State and Federal environmental regulations have created the push away from abrasive blasting. With the cost of constructing environmentally sound containment structures, and disposal cost of abrasive blast media increasing, alternative techniques are growing in popularity. Even the United States Navy has joined in this campaign with the adoption of written and visual standards for high pressure water jet surface preparation. The acceptance of water jetting (10,000 – 40,000 psi) as a preferred surface preparation technique is not solely a financial move.

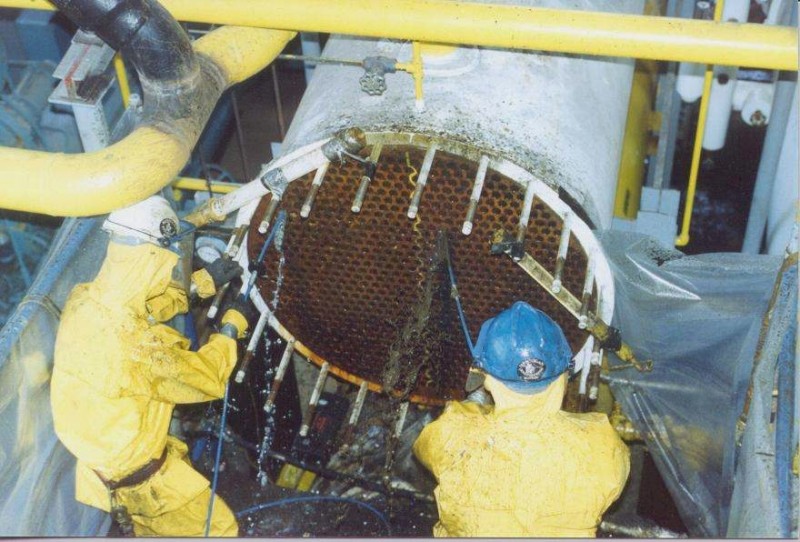

A properly cleaned and maintained utility system is crucial to the health and the longevity of the plant. Maintaining these systems not only removes abrasive and chemical contaminates that can over time damage systems, but also removes flow restrictions and fouling that prevents the plant systems from operating at maximum design efficiency.

Hennigan Engineering has the expertise and the specialized equipment to remove product build-up, dirt, oil, corrosion scale, and failed coatings down to the substrate and follow-up with a recommended coating system application for steel and concrete surfaces.

Looking over a long history of Hennigan’s service to Canal Electric Company, I wanted to take the opportunity to commend you for many jobs well done! In an era of uncertainty, it is reassuring to have the certainty of reliability, professionalism, and the commitment of excellence in service.Canal Electric

In conclusion, it is Design Engineering’s recommendation to use Hennigan Engineering to clean any of the-RBS heat exchangers during RF-3 that need cleaning. Hennigan’s past performance plus their patented hydrolasing tip make them the logical choice to use here at RBSRiverbend Nuclear Group

I would like to take this time to express the quality of work that Hennigan Engineering performed during the repair of the USNS Gordon for Boston Ship Repair, Inc. Hennigan Engineering showed professionalism in all aspects of the work that was performed in the shipyard. Work was done in a timely and efficient manner.Boston Ship Repair, Inc.

Or give us a call directly to discuss your industrial cleaning/coating needs:

800-472-8484