Hennigan Engineering was selected by the Emerson Swan Company to become certified service technicians for their Alfa-Laval Plate & Frame Heat Exchanger product line. The training program included intensive and technical classroom instruction as well as hands-on work at the Alfa-Laval factory located in Richmond, Virginia.

Alfa Laval is a Swedish company, founded in 1883. They began in the solution separation business and now manufacture a wide variety of specialized products and solutions for the industrial, power generation, marine, pharmaceutical and other industry across the globe. The company employs more than 18,000 people, the majority of whom are located in Sweden, Denmark, India, China, the US and France.

Emerson Swan is a nationally recognized, stocking manufacturer’s representative organization primarily serving the Northeastern United States and the Greater Toronto Area. Hennigan Engineering is now Emerson Swan’s primary service contractor for the Alfa Laval plate and frame product in the field.

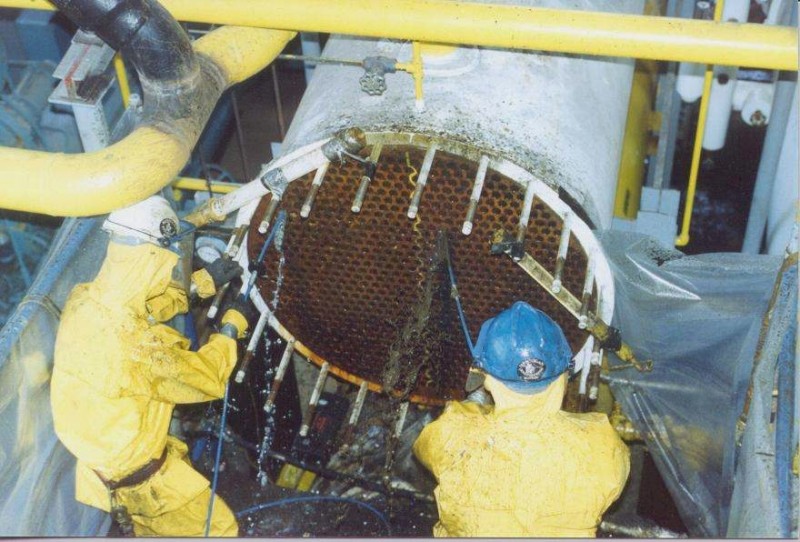

Our training includes plate & frame heat exchanger inspection, troubleshooting and diagnosis, unit inspection, troubleshooting and diagnosis, unit assembly/dis-assembly, gasket replacement, plate inspection, plate cleaning and frame inspection etc.

Most recently, our factory certified credentials allowed us to secure a plate & frame heat exchanger repair project at the Massachusetts Institute of Technology Cogeneration power plant in Cambridge Massachusetts as our first Alfa Laval certified Project for 2016.

Looking over a long history of Hennigan’s service to Canal Electric Company, I wanted to take the opportunity to commend you for many jobs well done! In an era of uncertainty, it is reassuring to have the certainty of reliability, professionalism, and the commitment of excellence in service.Canal Electric

In conclusion, it is Design Engineering’s recommendation to use Hennigan Engineering to clean any of the-RBS heat exchangers during RF-3 that need cleaning. Hennigan’s past performance plus their patented hydrolasing tip make them the logical choice to use here at RBSRiverbend Nuclear Group

I would like to take this time to express the quality of work that Hennigan Engineering performed during the repair of the USNS Gordon for Boston Ship Repair, Inc. Hennigan Engineering showed professionalism in all aspects of the work that was performed in the shipyard. Work was done in a timely and efficient manner.Boston Ship Repair, Inc.

Or give us a call directly to discuss your plate & frame heat exchanger cleaning needs:

800-472-8484